i.

Carrier tests:

In carrier tests, the carrier such as a silk or catgut thread or a penicylinder (a little stick) is contaminated

by submersion in a liquid culture of the test organism.

The carrier is then dried and is brought in contact with the disinfectant for a given exposure time. After the exposure, it is cultured

in a nutrient broth; no growth

indicates activity of the disinfectant tested whereas growth

indicates a failing.

Example of a carrier test is the in use-dilution test of the American Association of

Official Analytical Chemists (AOAC, 1990).

E.g. In Use-dilution test:

The AOAC Use-dilution test is a carrier-based test. The organisms

used are Salmonella cholerasuis, S. aureus and P. aeruginosa. Carriers (stainless

steel cylinders) are meticulously cleaned, sterilized by autoclaving in a

solution of aspargine, cooled and

inoculated with a test organism by immersing in

one of the culture suspensions. The cylinders are drained on filter paper, dried at 37°C for 40 minutes, exposed

to the use-dilution of the disinfectant for 10

minutes, and cultured

to assess the survival of the bacteria

ii. Suspension tests:

In these tests, a sample of the bacterial culture is suspended into the disinfectant solution and after exposure it is verified by

subculture whether this inoculum is killed

or not. Suspension tests are preferred

to carrier tests as the bacteria are uniformly exposed

to the disinfectant. There are different kinds of suspension tests:

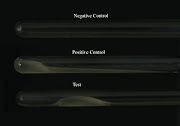

a. The qualitative suspension tests,

b. The quantitative suspension tests and

c. The test for the determination of the

phenol coefficient (Rideal and Walker, 1903)

a.

Qualitative test:

In this test, a loopful of bacterial suspension

is brought into contact with the disinfectant and again a loopful

of this mixture was cultured for

surviving organisms. Results are expressed as ‘growth’ or ‘no

growth’.

b.

Quantitative

methods:

In this

method, the number of surviving organisms is

counted and compared to the

original inoculum size. By

subtracting the logarithm of the

former from the logarithm of the latter, the decimal log reduction or microbicidal effect (ME) is obtained. An ME of 1 equals to a killing of 90% of the initial number of bacteria,

an ME of 2 means 99% killed.

A generally accepted

requirement is an ME that

equals or is greater than 5: at least 99.999% of the germs are killed.

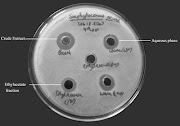

c. Phenol

coefficient test:

Phenol

coefficient may be defined as the

killing power of germicide or an antimicrobial agent towards a test organism compared

to that of phenol under identical conditions. It is the ratio

of the higher dilution of disinfectant killing the test organism in 10min. but not in 5min, to the of the highest

dilution of phenol showing the same result.

Procedure

— To a

series of dilutions of disinfectant being tested (5 ml per tube), 0.5 ml of

24hrs broth culture of test organism

(Staphylococcus aureus or Salmonella typhi) is added

— All tubes (disinfectant + organisms & phenol+ organisms)

are placed in 20°C water bath.

— At intervals of 5, 10 and 15 min, subcultures are made with a loop into sterile media tubes and

incubated for 48-72 hrs at 37°C and then observed for growth.

— The greatest dilution of disinfectant killing the test organism in 10 min

but not in 5 min is divided

by the greatest dilution of phenol showing the same result.

— The number obtained by this division is the phenol coefficient of the substance tested.

Table 1: Phenol coefficient method

|

Antimicrobial

agents

|

Dilutions

|

5 min

|

10

min

|

15

min

|

|

Disinfectant (X)

|

1:100

1:125

1:150

1:175

1:200

|

0

+

+

+

+

|

0

+ 0

+

+

|

0

0

0

0

+

|

|

Phenol

|

1:90

1:100

|

+

+

|

0

+

|

0

+

|

E.g. I: Rideal and Walker method;

It is developed by Rideal and Walker in 1903. In this technique, phenol is diluted from 1:400 to 1:800 and the

test disinfectant is diluted

from 1:95 to 1:115 and their bactericidal activity is determined against Salmonella typhi suspension.

Subcultures are performed from both

the test and phenol at intervals of 2.5,

5, 7.5 and 10 minutes. The plates are incubated

for 48-72 hours at 37°C.

That dilution of disinfectant

which disinfects the suspension in a given time is divided by that dilution

of phenol which disinfects the suspension in same

time gives its phenol coefficient.

Table 2: Rideal and Walker method

|

Disinfectant

|

Dilution

|

2.5

min

|

5 min

|

7.5min

|

10

min

|

|

Test disinfectant

|

1:400

1:500

1:600

1:700

1:800

|

NG G G G G

|

NG NG G G G

|

NG NG NG G G

|

NG NG NG NG G

|

|

Phenol

|

1:95

1:100

1:105

1:110

1:115

|

G G G G G

|

NG G G G G

|

NG NG G G G

|

NG NG NG NG G

|

Here, after 7.5

minutes, the test organism was killed by the test disinfectant at a dilution of 1:600. In the same period

the test organism was killed by phenol at a dilution of 1:100.

Phenol coefficient = 600/100 = 6

This result

indicates that the test disinfectant can be diluted six times as much as phenol and still

possess equivalent killing power for the test

organism

E.g. II: Chick Martin test

This test also determines the phenol coefficient of the test disinfectant. Unlike in Rideal-Walker method where the test is carried out in water, the disinfectants are made to act in the presence of yeast suspension (or 3% dried human feces) to simulate the presence of organic matter. Time for subculture is fixed at 30 minutes and the organism used to test efficacy is S. typhi as well as

S. aureus.

iii. In

capacity tests:

This test also determines the phenol coefficient of

the test disinfectant. Unlike in Rideal-Walker method where the test is carried out in water, the disinfectants are made to act in the presence of yeast suspension (or 3% dried human feces) to simulate the presence of organic matter. Time for subculture is fixed at 30 minutes

and the organism used to test efficacy is S. typhi as well as S. aureus.

In this method,

a soiled instrument is placed into a container with disinfectant; a certain quantity

of dirt and bacteria is added tothe

solution. The ability to retain

activity in the presence of an

increasing load is the capacity of the disinfectant. In a capacity test, the

disinfectant is challenged

repeatedly by successive additions of bacterial suspension until its capacity to kill has been exhausted. Capacity tests

simulate the practical situations of

housekeeping and instrument disinfection. The Best known capacity test is the

Kelsey-Sykes test (Kelsey and

Sykes, 1969).

E.g.

Kelsey and Sykes:

— It is

a triple challenge test, designed to determine

concentrations of disinfectant that

will be effective in clean and dirty condition

— The disinfectant is challenged by three successive additions of a bacterial suspension during the course of

the tests

— The concentration of the disinfectant is reduced by half by the addition of organic matter (autoclaved yeast cells), which builds

up to a final concentration of 0.5%

— Test organism used includes selected S. aureus, P. aeruginosa, P. vulgaris and E. coli

— The

method can be carried out under 'clean' or 'dirty‘conditions. The dilutions of the disinfectant are made in hard water for clean conditions and in yeast suspension for dirty conditions.

— Test organism

alone or with yeast is added at 0, 10 and 20 minutes interval. The contact time of disinfectant and test organism is 8 min.

— The

three sets of five replicate cultures

corresponding to each challenge are incubated at 320C for 48 hours and growth is assessed by turbidity.

— The

disinfectant is evaluated on its

ability to kill microorganisms or lack of it and the result is reported as a pass or a fail and not as a coefficient.

— Sets that contain two or more negative

cultures are recorded as a negative result.

— The disinfectant passes at the dilution

tested if negative results are

obtained after the first and second challenges.

— The third challenge

is not included in the pass/fail

criterion but positive

cultures serve as inbuilt

controls

Table 3: Kelsey and

Sykes method

|

Inoculum count

|

8 minute incubation

(1st set)

|

18 minute incubation (2nd set)

|

28 minute incubation (3rd set)

|

Result

|

|

2X109

|

+++++

|

+ + + + +

|

+

+ + + +

|

Fail

|

|

2X109

|

- - - - +

|

- - + + +

|

+ + + + +

|

Pass

|

|

2X109

|

- - - - -

|

- - - - -

|

- - - - +

|

Pass

|