SOLID WASTE TYPES

Source | Typical waste generators | Types of solid wastes |

Residential | Single and multifamily dwellings | Food wastes, paper, cardboard, plastics, textiles, leather, yard wastes, wood, glass, metals, ashes, special wastes (e.g., bulky items, consumer electronics, white goods, batteries, oil, tires), and household hazardous wastes.). |

Industrial | Light and heavy manufacturing, fabrication, construction sites, power and chemical plants. | Housekeeping wastes, packaging, food wastes, construction and demolition materials, hazardous wastes, ashes, special wastes. |

Commercial | Stores, hotels, restaurants, markets, office buildings, etc. | Paper, cardboard, plastics, wood, food wastes, glass, metals, special wastes, hazardous wastes. |

Institutional | Schools, hospitals, prisons, government centers. | Same as commercial. |

Construction and demolition | New construction sites, road repair, renovation sites, demolition of buildings | Wood, steel, concrete, dirt, etc. |

Municipal services | Street cleaning, landscaping, parks, beaches, other recreational areas, water and wastewater treatment plants. | Street sweepings; landscape and tree trimmings; general wastes from parks, beaches, and other recreational areas; sludge. |

Process (manufacturing, etc.) | Heavy and light manufacturing, refineries, chemical plants, power plants, mineral extraction and processing. | Industrial process wastes, scrap materials, off-specification products, slay, tailings. |

Agriculture | Crops, orchards, vineyards, dairies, feedlots, farms. | Spoiled food wastes, agricultural wastes, hazardous wastes (e.g., pesticides). |

SOLID WASTE MANAGEMENT

Management of solid waste is an important part which not only prevents the environmental pollution but also generates the valuable products for commercial uses e.g. ethanol, compost metabolites by utilizing special wastes and cooking gas.

Nowadays management of hazardous waste is given keen interest in order to prevents the spread of infectious diseases by poor management

The management of waste comprises various stages which are given as:-

1. Collection

2. Transfer

3. Disposal

4. Potential methods of disposal

1. Collection Methods/Tranportation

Proper collection & transportation processes are essentials part of solid waste management system. Nearly 70-80% of total cost is required for collection & transportation of waste. The basic collection method in developing countries is from community collection point. The basic collection methods in

The simple & best methods to collect the waste comprise the daily collection of the waste especially during summer & rainy seasons. If wastes are not collected daily, it generates odor problem & chances of spreading of microbes into the environment (air & water).

In developed countries block collection & curbside collection are common methods.

A. Block Collection

Individuals bring waste in containers to a carryings vehicle which travels a regular route twice or thrice a week. The containers are emptied by vehicle crew & returned to the individuals.

B. Curbside Collection

The Waste is brought in containers & placed on the footway at special places, which is collected later by cranes of solid waste management department and leave the containers at sample place.

For transportation in a developing countries simple hard carte are effective in many places due to lack of manpower, wide streets & vehicles. However, special vehicles are in compound practice to collect the waste from containers & solid waste collection centre.

The waste in the tractors & trucks are covered with plastics in order to prevent spreading of waste into the air & transported to final disposal place.

In the developed countries, government provides containers to the individuals in order to collect biodegradable & non-biodegradable wastes separately. Peoples themselves separate the recyclable waste & non-recyclable & transfer it to the collection containers. This practice makes an easy economical disposal method / Recycle method.

3. Disposal of waste

The process of selection of right solid waste disposal method is a complex one due to heterogeneity of the urban waste, but an appropriate method can save money as well as reduces the chances of problems occurs in future.

The disposal methods should be selected in such a way that the present situations are fulfilled & future situations are anticipated. The methods should also provide opportunity for recycling of materials if possible and should not pollute the air, ground water, surface water & the land water.

Several disposal methods are being using the various parts of the world. Among the various methods, sanitary landfill is applied in developed countries while open dumping is practiced in developing countries.

A. Hog feeding

B. Open dumping

C. Incineration

D. Sanitary landfills

E. Composting

F. Pyrolysis

G. Pulverization

H. Controlled tipping

I. Pulverization combined with controlled tipping

J. Ocean Dumping and River Dumping

A. Hog feeding

It is an old method of solid waste (particularly kitchen waste) management practiced in many countries property controlled; waste can be converted into the wealth previously hogs were used as scavengers of raw garbage but the leads to the spread of several bacterial, viral & parasitic diseases to animal and human beings. This problem is overcome by steaming of garbage for ½-1 hours before feeding to the hogs. This method is applicable in the cities covered with rural areas where hog farming is possible. In many terai regions of

B. Open Dumping

Open dumping of solid waste is practiced extensively in developing countries because it is cheap & requires no planning. Generally low lying areas & out skirts of town and cities are used for this purpose open dumps course public health problems by encouraging the breeding of files, rats, mosquitoes and other pets. Files can transmit typhoid, fever, cholera, dysentery, tuberculosis, anthrax & other disease; rats which can transmit typhoid, leptospirosis, rickettsial pox & cockroaches & mosquitoes transmit malaria, yellow fever, dengue, encephalitis, filarial etc. They also become a source of objectionable odors & course air pollution when the wastes are buried in order to reduce their volume & conserve space.

C. Incineration

Incineration is also a commonly used method which involves the burning of waste a high temperature. After burning ashes, glass, metals & other unburned materials account for 25% of total waste. The remaining materials are to be needed disposal safety by after methods such as sanitary landfill or by dumping or recycling. Incineration leads to ambient air pollution if incinerators are not properly designed, equipped (operate) properly. This method is useful when availability of land is limited as well as safe disposal of hazardous waste such as waste from nursing homes, hospitals, laboratories. Incineration results into the formation of some air pollutants which are ash, SO2, Hydrogen chloride & organic acids. New techniques for the handling of waste involves the separation of non-combustible part by magnetic or gravity separation methods & recycle them. This technique encourages the recycling of waste as well reduces the total cost needed for incineration. Incineration is widely applied techniques for the disposal of solid waste generated in the industries. The design of incinerator used is depend upon combustibility & nature of waste to be disposal. Another term commonly used for this technology is energy recovery or waste to energy because the heat derived from incineration refuse is a useful resource. The heat energy liberated could be used to generate electricity. Internationally well over 1500 waste to energy plants in

Advantages | Disadvantages |

1. Energy generation. 2. Volume reduction by 90% 3. Suitable from aesthetic hygienic and stand point 4. Requires small land area. 5. Inert materials such as ash is recovered, | 1. Initial investment is high. 2. Required skilled manpower. 3. High Maintenance cost 4. Air pollution |

D. Sanitary landfill

The landfill operation is essentially a biological method of waste treatment. The stabilization of waste may be divided into five distinct phases within overall process. During first phase of operation aerobic bacteria are dominant which consume oxygen. As a result of metabolism of bacteria temperature of the environmental increases. In the second phase anaerobic conditions established & hydrogen & CO2 gas are evolved due to fermentation of organic substrates. In the third phase of growth methanogens active to produce methane & CO2 gas. In the fourth phase methanogenic activity becomes stabilized. In the fifth phase the methanogenic activity decreases representation depletion of the organic matter & alternately the system returns to aerobic conditions within the landfills. The duration of each phase of prevailing environmental conditions & the nature of the waste. The end products of decomposition of wastes during phase three & four are mostly CO2 & CH4 gas along with a small amount of H2S, NH3 & water. During first year the amount of N2 decreases as air cannot penetrate the soil to the seated cell. Methane production can usually be observed around 200 days after reduce disposal. During construction the landfills site must be designed in such a way that there leach ate should be drained in proper manner to avoid surface & ground water pollution. Escape rents for gases should be provided they do not build up to dangerous levels. Landfills gas is renewable source of energy & which can be used for cooking purpose.

Advantages | Disadvantages |

1. Most economical method where land is available. 2. Minimum public health problem because files, rats & other pets are unable to breed in the covered waste. 3. Minimum fire hazards. 4. Can receive all types of waste, eliminating the necessity of separation of waste into degradable & non-biodegradable. 5. Finished landfills sites can be used for the development of parks, playground, golf courses etc. | 1. Unavailability of suitable land especially rears the crowded area. 2. Proper operation & skilled manpower needed for daily operation. 3. Danger of surface & ground water pollution if not properly selected & designed. 4. Sealing materials used do not remain effective permanently 5. Leakage of gases may cause odor problems. |

E. Composting

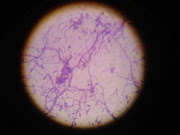

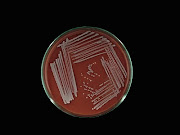

Composting of organic waste appears to offer an attractive alternative to landfill for decomposition of solid domestic and agricultural waste. In contrast to a sanitary landfill composting of refuse is an aerobic method of decomposing solid waste. It is microbial process that converts putrecible organic materials into stable humus like product that is reduced in bulk and can be used for soil improvement. The organisms included are bacteria which predominate at all stages, fungi which often appear after first week and actinomycetes which assist during final stages.

Initially the process starts with the mesophilic bacteria which oxidize the organic matter in the refuse to carbondioxide and heat the temperature rises to about 45°C and at that point the thermophilic bacteria take over and continue the decomposition. During this phase temperature further rises to about 60°C. During the operation the refuse is periodically turned over to allow the sufficient oxygen to penetrate to all parts of the material to support the aerobic life. After about 3 weeks the compost is stabilized and the end point of composting operation can be measured by a drop in temperature.

Composting process can be categorized into two types

- Aerobic process

- Anaerobic Fermentation process

E1. Aerobic process

In aerobic decomposition process microorganisms utilize oxygen to feed on the organic matter in the waste produce stable end product as well as their own biomass. The end product is humus like material which is extremely useful as plant nutrient. The aerobic fermentation process occurs very widely in nature and is the main way in which waste products from field and forest are converted into humus. Composting is accomplished in static piles aerated piles or continuous feed reactors.

The static pile process is simple but relatively slow, requiring many months for stabilization. Insects breeding and odor problem during static pile method can be controlled by covering the piles with a layer of soil, finished compost or wood chips. Under favorable conditions, self heating causes to rise in temperature to 55-60° C or above in 2-3 days. After few days temperature is gradually decreased. Oxygen concentration in the compost pile is five times lower than ambient air. Periodic turning of the compost piles help to saturate the waste with oxygen and uniform mixing. After thermophilic process, a curing phase at mesophilic temperature starts for several month. Hence, large land area is required due to slowness of the process.

The aerated pile process is substantially faster process through improved aeration. The aerated pile process involves the suction of air through perforated pipes buried inside the compost pile. This design, Beltsville process, achieves at least partial oxygenation of pile, but temperature control is inadequate. The temperature rises unto 70-80°C. This model is improved by

In continuous feed reactor process composting is carried out in a bioreactor. It requires about 20,000 cubic feet of air per ton of organic matter/day for efficient composting. This process forms a uniform & stable product but also requires a high initial investment. Composting in a reactor is accomplished in 2-4 days. A part or the entire reactor is maintained at thermophilic temperature using the heat produced in the composting process. After processing in the reactor, the product requires “curing” for about a month prior to packaging.

Regardless of the process design, conducting the composting process in the thermophilic temperature range is desirable because it speeds the process and destroys pathogens that may be present in feacal matter and in sewage sludge. The aerobic oxidation process catalyzed by microorganisms produce heat which increases temperature to 76-78°C. This temperature is inhibitory to biodegradation process i.e. for microbes because the maxiamal thermophilic activity of microbes occurs between 52-63°C. Aeration or turning or periodic cool water spraying can reduce temperature to an optimum level.

The composting process is initiated by mesophilic heterotrophs. As temperature rises, they are replaced by thermophilic forms. Thermophilic bacteria predominating compost piles are B. steriothermophilus, Thermomonospera, Thermoactinomyces, Clostridrum, and Thermocellum. Important fungi in composting process are Geotrichum condidum, Aspergillus fumigatus, Mucor pusillus, Chaetomium thermophile, Thermoascus auranticus and Torula thermophila etc.

Factors affecting composting:-

1. Moisture: - Optimum 50-60% moisture is essential. Above 70% or more interferes with aeration and lowers self heating capacity.

2. C:N ratio(Carbon: nitrogen ration):- Should not be greater than 40:1. Lower nitrogen content should not permit formation of sufficient microbial biomass. Excessive nitrogen content (25:1) tends to volatilization of ammonia causing odor problems and lowers the fertilizer value of compost. So optimum is about 27 to 30:1.

3. Temperature: - Optimum is around 60°C at which thermophilic activity is favoured. Temperature above 50-60°C is an essential to operate thermophilic activity and to kill pathogens (cells and cysts).

4. Aeration: - Most important to maintain temperature and hence most stable compost.

Steps in composting: -

E1. Separation of compostible and non-compostible:-

Organic- compostible, inorganic – non-compostible

Magnetic device separates tin, iron and other metals.

Manual or gravity separation method is used to separate glasses, bottles, rubber, plastic etc.

Separation at source is more economical than separation at collection centre or composting centre.

E2. Shredding: -

Once most of non-compostible materials have been removed, the rest is shred. This is necessary to give the materials a sufficiently large area for the microbial attack to proceed readily. Hammer mills are generally employed for shredding which reduce the size.

E3. Blending for composting:-

Blending causes to adjust C:N ratio. Some materials with poor nitrogen content (waste plant products, saw dust etc.) are blended with materials having very high C.N ration (human or animal excreta, slaughterhouse waste, etc). Soil is also added to adjust the moisture.

E4. Composting:-

Aerated pites or bioreactors (mentioned above).

Nusoil process: - The pulverized matter then goes to a vertical digester where decomposition takes place. The digester is a circular unit has seven sections. The waste moves down through each section of the digester. It is kept for about one day in each section & air flow rate & water addition are regulated so that decomposition takes place under optimum condition. The digestion process is completed in seven days & the resultant compost is satisfactory for direct field application without addition of supplementary nutrients.

E5. Curring & packaging:-

F. Pyrolysis: -

Pyrolysis is a method of solid waste disposal which results into chemical conversion of refuse to get new chemical compounds. Pyrolysis is operated using intense heat to cause chemical changes but not combustion. In Pyrolysis, the refuse is heated in an oxygen free environment during which most organic substrates can be split through a combination of thermal cracking and condensation reactions into gaseous, liquid and solid fractions. Pyrolysis is carried out in different reactors and three major component fractions resulting from pyrolysis are;

- A gas stream generated by pyrolysis may contain primarily hydrogen, methane, carbon monoxide etc. depending upon organic characteristics of the material being pyrolysed.

- A fraction that consists of tar and/or oil stream that is liquid at room temperature. It consists of chemicals like acetic acid, acetone and methanol.

- Solid fraction containing pure carbon plus inert materials.

G. Pulverization: -

Pulverization is really a step involved in disposal of refuse by sanitary landfill, composting or other techniques. It is the process of making small pieces of solid waste by pressing or cutting the separation conducted by the use of rotating drum machines. The pulverized waste can be easily disposed by applying other techniques.

G1. Rotating dram machines: - These pulverize the waste by attrition. Water is added to the crude refuse and mixes, is then passed into the revolving drums which have a circular, an octagonal or a hexagonal crops section. The drums operate either in a batch or continuous basis with number of rotations depending upon types of refuse. The drums usually contain a separation device for materials which cannot be broken down: -mainly plastics, rubbers and metals etc. The final materials that come out of drums normally contain a moisture 50-60% and density of 0.5-0.6kg/dm3, much higher than the original density of refuse. Drum-type pulverizers usually have a capacity of about 10-12 tons/hr and require about 35kw of power to operate. It is provided with magnetic separation to remove iron and tin.

G2. Hamper mills: - Hammer milling is operated either a dry or wet process. Hammer mills are of two types i.e. fixed hammer and swing-hammer type. The hammer mills can process maximum about 30 tons/day. It consists basically a horizontal rotor which carries a number of swinging or fixed hammers. It consists of impact plates and grates through which the processed refuse is finally ejected. Size of pulverized particles is about 5-8 cm in diameter. Metals are separated by shredding and iron is recovered by magnetic separators. Power consumption is about 150-200kw.

H. Controlled tipping: -

This method allows permanent deposition of waste on land, sealed in cells isolated from the surface with layers of earth. Controlled tipping is generally practiced in conjugation with land reclamation schemes, to reclaim marshes, exhausted quarries and gravel pits for agricultural, industrial and recreational uses. If not properly designed it will create water pollution problem and invoke the breeding of pests. If the reclaimed area is to be used for agriculture purpose, non-biodegradable compounds should be removed.

I. Pulverization and controlled tipping:-

Although cost is high it has few advantages: -

a) Less earth cover with required than unpulverized waste.

b) Rat, mice, insect larvae destroyed.

c) Land can be used for agriculture purpose.

d) Very less time will required for complete degradation of waste.

J. Ocean dumping/River dumping: -

It is one of the oldest methods and nowadays it is completely restricted.

4. Potential methods of disposal

1. Utilization.

2. Recovery and recycling: - paper, metal, plastic, glass.

29 comments:

Wonderful blog & good post on plastic management trash box. It's really helpful for me, contain the plastic trash in portable garbage can to use it afterwards. waiting for a more new post. Keep Blogging!

Nice post and good information on waste management. Thanks for sharing and you can also check waste management in india

Nice post and it's informative too. Thanks for sharing and you can also check waste disposal management

Great post. I was once checking constantly this weblog and I'm impressed! Extremely useful information specially the closing part. I maintain such information much. I was once seeking this specific information for a very long time. Many thanks and best of luck.

Skip Hire Sheffield

Incredible post. I was once checking continually this weblog and I'm dazzled! Incredibly valuable data exceptionally the end part. I keep up such data much. I was once looking for this particular data for an extremely significant time-frame. An abundance of thanks and most amazing aspect karma.

Skips Near Me

Incredible post. I was once checking continually this weblog and I'm dazzled! Incredibly valuable data exceptionally the end part. I keep up such data much. I was once looking for this particular data for an extremely significant time-frame. An abundance of thanks and most amazing aspect karma.

Skips Near Me

Great post and it's informative too. Thanks for sharing.

plastic waste management in india

Hi, I am George Albert, I lived in London, UK. I worried about how to clean my premises, I visited many other blogs . They provide me with great information but I need further, I need to check the previous. It will be a great gift. Thanks

Thank you so much to share an interesting article with us. I found lots of important information. Keep us updating. Also, Visit at Food Waste Management Australia.

Thankyou so much for sharing nice information related to Solid waste management solution.

It's an amazing post, thanks for sharing with us great information about waste. Waste Disposal Facility.

Thanks for sharing this blog. There are many points that are considered during hiring Plastic waste recycling company . I have also found something to related to Plastic waste recycling company there details are following as.

Nice blog. keep sharing.

Trash Collection

vikaspumps06@gmail.com vikaspumps Vikas@#2020

vikaspumps06@gmail.com vikaspumps Vikas@#2020

Nice Blog!

Vikas Pollution is leading one of the best manufacturer of Sewage Treatment Plant For School in Saharanpur, Uttar Pradesh.

Sewage Treatment Plant For School

Sewage Treatment Plant For Hospital

Sewage Treatment Plant For Malls

Sewage Treatment Plant For Building

Package Drinking Water Plant

Sewage Treatment Plant For Office

Sewage Treatment Plant For Dyeing Plant

Containerised Sewage Treatment Plant

Industrial Sewage Treatment Plant

Dynamically Sealed Pump

Dynamically Sealed Pump Manufacturers

Nice Blog! Thanks for sharing..Environment Management System

Thanks for sharing your knowledge with us!

If you are looking for effective essential oils Online in India, get them from mokshalifestyle:

Carrier oils

Essential oils

Essential oils india

Extracts

fragrance oil

hydrosols

Great post!! Nice Work.

sell scrap online

This is only good for those who are well-versed with the industry because the rest will be practically fodder.

commercial skip

Thank you so much to share an interesting article with us. I find lots of important information.

Solid waste management solution | iot based solid waste management system

I loveed to read the article of skip hire on this page. You Should follow this site for the best information and services.

Skip Hire Kent

Recycling old and damaged electronics can reduce the need to mine metals and it will reduce greenhouse gas emissions since old devices have been re-used for producing new ones. TVs, laptops, PCs, video consoles, cables, wires, smartwatches, remote controls, and mobile phones can all be recycled for metals such as copper, tin, iron, aluminium, carbon, titanium, gold, and silver. There are many materials used in making these electronic devices that can be recovered, reused, and recycle.

More Info : Waste Recycling in Dubai

Industrial waste incineration - MAEH is a truseted provider of certified industrial waste management company in Singapore. We also provide Industrial waste incineration in Singapore.

I just want to say that you're rocking, keep it up. Leaflet Printing in Bangalore

I really impressed after read this because of some quality work and informative thoughts. I just wanna say thanks for the writer and wish you all the best. Find the best plastic pyrolysis plant UK.

Nice Post!!

Please look here at Medical Waste Services

Thanks for sharing such really amazing information. Please keep us updated, Our IoT-based Solid Waste Management System automates the waste collection process and makes it more efficient.

RFID, NFC, and QR code technology

Incineration is a good choice for the disposal of waste, especially clinical materials and it is not harmful to the environment. Check this Waste Management in Melbourne, which uses incineration in destroying hazardous waste.

Post a Comment