CENTRIFUGATION

Centrifugation

is a basic separation technique. A centrifuge is a device for separating

particles in an applied centrifugal field in a solution.

There are two

different forces act on an object moving in a circular motion.

Centrifugal force:

Force

directed outward from the center. E.g. While

turning a bus in twist way, the passengers strike on the bus wall is due to

centrifugal force.

Centripetal

force:

The

force exerted towards the center is now as centripetal force. E.g. the force acts

on passengers by the turning car.

Now, suppose

a particle is exerted to sediment by centrifugal force, then

The rate or

velocity at which it sediments is proportional to the force applied

- Sedimentation

is more rapid when the force applied is greater than the gravitational

force of the Earth

- Basis of

separation is to exert a larger force than does the Earth’s gravitational

force.

Basic

Principle of Sedimentation

The

particles to be separated are suspended in a specific liquid media, held in

tubes or bottles which are located in rotor in centrifuge machine, positioned

centrally to the drive shaft. These particles are differing in size, shape and

density.

As

we have already mentioned that,

The rate of

sedimentation is dependent upon the applied centrifugal field (G)

G = W2R …………………………equ

(i)

Where

W: Angular velocity of revolving particle

(Remember: one revolution of the rotor is equal to 2 radians)

R: Radial

distance from axis of rotation

In terms of revolution per minute, we have W= 2p rev min-1/ 60

Therefore:

G = W2R

It

is expressed as a multiple of the earth’s gravitational field (g=981 cm s-2).

Hence

RCF,

Relative Centrifugal Field

= G / g

=

RCF = 1.119 x 10-5(rev min-1)2 R …………………………….equ (ii)

= x g unit

(number times g)

It

means, RCF is the ratio of the weight of the particle in the applied

centrifugal field to the weight of the same particle when acted by gravity

alone. Therefore the rotor speed, radial dimensions and time of the rotor must

be quoted during the centrifugation.

However:

This

is not the only case in Biochemical experiments as biological samples are

always found in dissolved or suspended form in a solution. Thus, the rate of

sedimentation not only depends on the centrifugal field but also on

1. Mass of particle

2. Density of particle

3. Density and viscosity of the medium

used

4. The extent to which its shape deviates

from spherical

Now according to Newton’s Second law of Motion, the centrifugal force (F) exerted on particle is

= M. a

= M. W2R

……………………………….equ

(iii)

Where:

M: mass of

particle

a:

acceleration while in angular motion= W2R

Increasing

the sharpness of a turn, w and r decreases. Since r is linear, w has greater

effect on the particle.

It

causes the molecules to sediment down the centrifuge tube. They start to move

downward to sediment; however they encounter opposing force, a frictional

resistance in their movement.

Frictional

force = f

= 6p. h. Rp.

) ……………………………equ (iv)

Where:

f: Frictional force

dr/dt: Rate

of sedimentation expressed as the change in radius with time (velocity v)

h: Viscosity coefficient of medium

Rp: Radius

of sedimenting particle

The

sedimenting molecule must also displace the solvent into which it sediments and

give rise to a buoyant force

Buoyant force =

mass x a

= V. dm W2R ……………………..equ (v)

Where:

V: Specific volume of the molecule

dm: Density of

the medium

While

sedimenting, the velocity of the particle increases until it equals the

frictional force resisting its motion through the medium. This is an

equilibrium state when the particles stop to move or sediment. From equations

iii, iv and v.

Centrifugal force =

Frictional force + Buoyant force

M. W2R =

6p. h. Rp.

) + V. dm W2R

v =

h Rp2 (dp - dm) W2R ……………………………..equ

(vi)

Where:

dr/dt: v, is

the velocity of the sedimenting particle

Mass: Density x Volume

dp: Density of particle

dm: Density of

medium

From above equation, it seems clear that velocity is proportional to its size, to the differences in density between the particle and medium and to the applied centrifugal field. It is zero when the density of the particle and medium are equal. It decreases when the viscosity of the medium increases.

Since the Rp is in square form, the size of particle has greater influence on velocity.

For

a particle, h, Rp, dp, dm and W all are

constants

t =

In

Where

t: The sedimentation time in seconds

Rt: Radial distance from the axis of rotation

to liquid meniscus

Rb: Radial

distance from the axis of rotation to bottom of tube

It is now clear that a mixture of heterogeneous approximately spherical particles can be separated by centrifugation on the basis of their densities, their sizes and etc.

t µ

It means, higher the size particles, faster is the sedimentation (Short time for sedimentation) of it and smaller the size slower is the sedimentation (takes longer time).

CENTRIFUGATION: RCF CALCULATION

The relative centrifugal force (RCF) can be calculated from

the following equation:

RCF = (1.119 x 10-5) (rpm)2(r)

Where rpm is the speed of rotation expressed in revolutions per

minute and r (radius) is the distance from the axis expressed in cm. The RCF

units are "x g" where g represents the force of gravity. RCF

can also be determined from the NOMOGRAPH

below. Place a straight edge to intersect the radius and the desired RCF to

calculate the needed rpm. Alternatively place the straight edge on the radius

and the rpm to calculate the g-force. For example, spinning a sample at 2500

rpm in a rotor with a 7.7 cm radius results in a RCF of 550 x g.

Figure 1: Nomograph

showing relationship between RCF, RPM and Radius

Centrifuges and their uses

Centrifuges and their uses

1.

Low Speed Centrifuge

·

Least expensive and simplest in many design

·

Maximum rotor speed of 4000-6000rpm (3000-7000 X g)

a) Small

bench centrifuges

·

To collect small amounts of materials (250mm3) that is

rapidly sediment (1-2 min)

·

No special cooling system

·

Ambient air flows around the rotor to cool the system

·

Use to rapid sedimentation of blood samples

b) Large

capacity refrigerated centrifuges

·

Refrigerated rotor chambers for cooling the sample

·

Large volumes 10, 50 and 100 cm3 processing depending

upon the rotors and tubes

·

Maximum capacity of 1.25 dm3

·

Rotors are mounted on a rigid suspension

·

Erythrocytes, coarse or bulky precipitates, yeast cells, nuclei

and chloroplasts

2. Microcentrifuge

·

Maximum rotor speed of 12000rpm with RCF of 10000g

·

Have total capacity of 1.5ml over very short time (0.05-5 min)

·

Use to sediment large particles like cell ppt

3. High speed refrigerated centrifuge

·

Maximum rotor speed of 25000rpm with RCF of 60000g

·

Have total capacity of 1.25 dm3

·

Interchangeable fixed angle and swinging buckets rotors

·

Use to collect microorganisms, cellular debris, larger cellular

organelles and proteins precipitates by ammonium sulphate

·

Not use for viruses and smaller organelles like ribosome

4. Continuous flow centrifuge

·

Relatively simple and high speed centrifuge

·

Special design rotor (long and tubular) with non interchangeable

system

·

Have total capacity of 1-1.25 dm3/min with continuous

flow

·

Particles sediment at wall and excess clarified medium overflows

through an outlet port

·

Use to collect bacterial and yeast cells from their mass culture

of about 100-500 dm3

5. Ultracentrifuge

·

Powerful with speed

·

2 types

a) Preparative ultracentrifuge

- Maximum rotor speed of 30000-80000 rpm

with RCF of 600000 x g

- Highly sophisticated with refrigerated,

sealed and evacuated to minimize excess heat generate

- More sophisticated temperature

monitoring system employing an infrared temperature sensor

- Overspeed control system to prevent

operation of rotor above its max rated speed

- Vibration minimize system (a flexible

drive shaft system) during unequal loading of the centrifuge tubes

- Enclosed in heavy armour plating

- Airfuse for some biochemical

applications requiring high centrifugal force

- Use for sediment macromolecule/ligand

binding kinetic studies, steroid hormone receptor assays, separation of

major lipoprotein from plasma and deproteinisation of physiological

fluids for amino acid analysis

b) Analytical ultracentrifuge

- Maximum rotor speed of 70000 rpm with

RCF of 500000 x g

- Highly protective chambers with

refrigerated and evacuated system also have an optical system to enable

the sedimenting material to be observed throughout the process.

- Three types of optical system, a light

absorption system, alternative Schlieren system and Rayleigh

interferometric system (both measures refractive index of solution)

Design and types of Preparative Rotors

- These are rotating instruments in

Centrifuges

- During rotation at high speed, higher

stress forces generated

- Made up of aluminum alloy and titanium

alloy which don’t rust-brass, steel or Perspex

- Can tolerate nearly twice the centrifugal

force of rotors

- Protective coating to the metal surface

by anodizing or by applying black epoxy paint

- Various types of rotors

a)

Swing bucket

rotors

·

Common in low speed centrifuges

·

Also high speed, ultracentrifuges

·

Tubes accommodated

in a pivoted bucket which rotates from a vertical to a horizontal position

during acceleration

·

Bucket returns to vertical as centrifuge decelerates

·

Meniscus of sample always remains at right angles to axis

of tube

·

Six-place rotor (6 buckets) most useful – can spin 2,3,4 or

6 samples (or sets of samples)

·

Pelleted material symetrically distributed in a

hemisperical section at bottom of tube

·

Only particles in bottom of tube which move directly to

bottom

·

Other particles move first to wall of tube, then towards

bottom

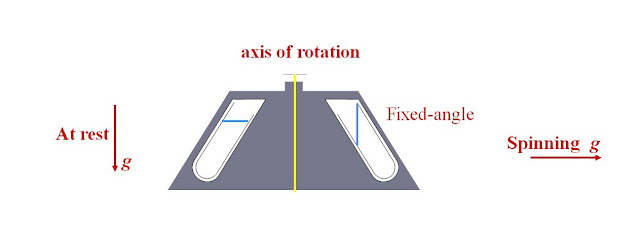

Figure 2:

Swinging-bucket rotor and its spinning

b)

Fixed-Angle Rotors

·

Tubes in pocket at fixed angle in rotor

·

Angle 10 to 50 degrees from vertical – at rest and during

spin

·

Use up to 600,000 x g

·

Particles migrate to wall before moving towards bottom

·

Pellets always asymetrically distributed toward the outer

aspect of the bottom of the tube

Figure 3: Fixed-angle

rotor

c)

Vertical Rotors

·

First introduced in 1970’s – high-speed and

ultracentrifuges

·

Solution re-orientates below 800 rpm, no disruption to

gradient

·

Good for isopycnic and rate-zonal centrifugation

·

Not used for pelleting – pellet would be along length of

tube and would fall off as liquid decanted

·

Also – “near-vertical” rotors – tube angle = 8 degrees

Figure 4: Vertical or near

vertical rotor

Figure 5: Axis of rotation

SEPARATION METHODS IN PREPARATIVE ULTRACENTRIFUGATION

1.

Differential Centrifugation: The process of differential centrifugation is based on the fact

that organelles have differences in size, shape and density. As a result, the

effect of gravity on each is different. We can use this principle to separate

an organelle from a homogenous solution of particles by artificially

controlling the gravity of a solution. This is done by putting the solution in

a variable speed centrifuge and rotating them at a high rate of speed. This

creates a force that can be much greater than the force of gravity, and

particles that would normally stay in solution will fall out and form a pellet

at the bottom of the tube.

Differential centrifugation

schemes involve stepwise increases in the speed of centrifugation. At each

step, more dense particles are separated from less dense particles, and the

successive speed of centrifugation is increased until the target particle is

pelleted out. The final supernatant is removed, the pellet is resuspended and

further study or purification can be done on it. The fractionation of rat liver

is an example of how this process works:

Figure 6: Separation

of cell fractionate by Differential Centrifugation

Figure 7: Separation of cell organelles from rat liver fractionate by Differential Centrifugation

2. Density Gradient Centrifugation

Density

gradient centrifugation is a technique that allows the separation of cells,

organelles and macromolecules, depending on their size, shape and density.

A density gradient is created in a

centrifuge tube by layering solutions of varying densities with the dense end

at the bottom of the tube. Cells and large molecules are usually separated on a

shallow gradient of sucrose or other inert carbohydrates even at relatively low

centrifugation speeds, while macromolecules such as proteins and nucleic acids

are separated at higher centrifugation using ultracentrifuges.

Criteria for an ideal density gradient centrifugation medium are:

- the

additive must form a solution within the required density range

- the

additive must not interfere with, or damage, the sample

- the solvent

must be compatible with the sample

- the

solution must have a refractive index within the practical range, as well

as a low viscosity

- The

additive must be easily removable from the sample.

The additives for density gradient centrifugation can be divided

into four main categories:

These

solutions fulfill most of the above requirements. However, due to the high

ionic strength, hydrogen bonding within biological macromolecules (protein,

nucleic acid - protein complexes) is impaired by a chaotropic effect. Therefore

these salts are mainly used for DNA and RNA separations. Cesium chloride is

used most frequently. Other useful salts include sodium iodide, sodium bromide,

cesium sulfate and cesium acetate. Potassium tartrate has been used to separate

viruses from host cells.

It should be kept in mind that the density of the sample is highly dependent on the hydration of the macromolecule, which in turn depends to a large extent on the dehydration power of the salt solution.

In this class

of compounds sucrose is most widely used. It has a useful density range of up

to 1.29. This range can be increased to 1.37 by addition of glucose or by

dissolving sucrose in D2O. Sucrose has very little effect on

macromolecules, but affects enzyme activity. Due to its high osmotic pressure,

sucrose solution dehydrates cells and their organellae very efficiently.

Glycerol solutions are the preferred media for the separation of enzymes

because they do not affect enzyme activity. They exhibit a high viscosity,

requiring prolonged centrifugation times. More importantly however, glycerol

penetrates biological membranes.

3.

Hydrophilic Macromolecules

Dextran

gradients have been used for the separation of microsomes. Separations achieved

with dextrans show similar results to those obtained by using synthetic

sucrose/ epichlorohydrin co-polymers. In some cases bovine serum albumin has

been applied, but the preparation of an appropriate solution is very difficult.

4.

Synthetic Molecules

These

additives are the sodium or methyl glucamine salt of triiodobenzoic acid and of

metrizoic acid. It should be kept in mind that the parent acid of these salts

may precipitate on adjusting the pH to acidic values. Metrizamide, a covalently

bonded compound of glycosamine and metrizoic acid is most widely used. This

additive forms solutions of relatively low viscosity. These solutions are

stable over a wide range of pH and ionic strength, and show practically no

interference with the analytes.

Density gradient centrifugation

methods are of two types, the rate zonal technique and the isopycnic

(isodensity or equal density) technique.

Rate

Zonal Technique: When mixtures of cellular extracts are layered on top of a

density gradient in a tube and subjected to centrifugation, the various

components move through the gradient at different rates that are dependent on

their sizes and shapes. These different components appear as distinct bands or

zones in the gradient with large components migrating farthest in the tube in a

given period of time. The rate with which a fraction moves the fixed distance

in the gradient tube is dependant of its sedimentation value (S) that, in turn

is determined by the size and shape of that fraction. By comparing the

different position of the components in the gradient, it is possible to make an

approximate measurement of their molecular weight. It is, however, difficult to

precisely determine these molecular weights, as this requires knowledge about

the shape of these molecules, which is hard to determine with accuracy. This

density gradient separation technique is called rate zonal centrifugation and is

usually performed with a shallow sucrose gradient. The different components

being separated by this technique are denser than any of the sucrose

concentrations used in the gradient. Samples are, therefore, centrifuged just

long enough to separate the components of interest. Longer centrifugation than

necessary would allow all components to form a pellet at the bottom of the

tube. One of the most important applications of this technique over the past

decades was the separation of transfer RNA (4S) from ribosomal RNA

that forms three different classes with distinct sedimentation values 23S, 16S

and 5S. This helped to facilitate the characterization of the protein

synthesizing system.

Figure 8:

Rate zonal Density Gradient Centrifugation

Isopycnic

Technique: A second density gradient technique, called equilibrium

density-gradient centrifugation is used to separate cellular components on the

basis of their buoyant density. In this case the cellular mixture is

centrifuged through a steep density gradient that contains a high concentration

of sucrose, or more often, cesium chloride (CsCl). In these gradients, the

molecules being studied have a density somewhere in between the highest and

lowest densities of sucrose or CsCl generated in the gradient. The components

of a sample begin to move down this gradient in the same way as they do in a

rate-zonal density gradient. When a component of the mixture reaches a point where

the density of the solution is equal to its own density, it stops moving

further and forms a distinct band. The position of the band in the tube is

characteristic of the buoyancy of that component. Buoyancy or buoyant density

of a substance is its tendency to float in a medium, which in this case is the

density gradient. Hence soluble proteins which have similar density (p=1.3 g cm-3

in sucrose solution) cannot usually be separated by this method, whereas

subcellular organelles (e.g. Golgi apparatus p=1.11 g cm-3,

mitochondria p=1.19 g cm-3 and peroxisomes p=1.23 g cm-3in

sucrose solution can be effectively separated.

Figure: Isopycnic Density Gradient Centrifugation

Equilibrium density gradient

centrifugation using CsCl was for decades the method of choice in the

purification of highly pure plasmid DNA. Meselson and Stahl, who

developed this technique, were the first to use it in an experiment that

provided evidence for the semi-conservative replication of DNA and

confirmed the double helix structure of DNA proposed by Crick and

Watson.

Application of Centrifugation

—Basic separation of

Biomolecules

—Purification of

mammalian cells

—Fractionation of

subcellular organelles (including

—membranes / membrane

fractions)

—Fractionation of

membrane vesicles

—Identification of

molecules

Extensive tool in

molecular biology

2 comments:

Valuable for information.. Is there any further reading you would recommend on this?

Ally

High Speed Centrifugei

This is the best Separation Technique

Thanks for sharing useful information.

We provides result oriented SEO services in Vadodara.

Visit Our WebsiteSEO Agency in Vadodara

Post a Comment