A. DISC DIFFUSION METHOD

FOR THE ANTIMICROBIAL SUSCEPTIBILITY TESTING

principle:

A standardized

inoculum of bacteria is swabbed onto the surface of a Mueller Hinton agar (MHA)

plate. Filter paper disc impregnated with antimicrobial agents are placed on

the agar. After overnight incubation, the diameter of the zone of inhibition is

measured around each disc. By referring to the tables in the CLSI disc

diffusion standard, a qualitative report of susceptible, intermediate or

resistant is obtained.

Quality control:

A. QC strains

1. Escherichia

coli

ATCC 25922 2. Staphylococcus aureus ATCC 25923

3. Enterococcus faecalis ATCC

29212

B.

Monitoring accuracy

1. Test QC strains by following routine

procedure, and record results. Record lot number and expiration date of discs

and agar.

2. Compare to expected results (CLSI QC

tables). Note any out of control result and document; proceed with corrective

action, if necessary.

3. Perform daily and weekly QC testing.

PROCEDURE:

- Brings agar plates and canisters of

discs to room temperature before use. Agar plates may be removed from

refrigerator and placed in a 35 C ambient air incubator with lids slightly

ajar to evaporate excess moisture. Do not leave in incubator for longer

than 30 min.

- Inoculum preparation

Using a loop or swab, transfer colonies as follows

- Direct colony suspension

method: - pick several colonies from a fresh (18 – 24 hr) nonselective

agar plate to broth or 0.9% NaCl.

- log phase method

a. Pick

four or five isolated colonies to 3.0 to 5.0 ml of broth.

b. Incubate

at 35 C for 2 to 8 hr until growth reaches the turbidity at or above that of a

0.5 McFarland standards.

- For either the log phase or

direct colony suspension method, vortex well and adjust turbidity

visually with sterile broth or 0.9% NaCl to match a 0.5% McFarland

standard.

- Inoculation of agar plates

- Within 15 minutes of

adjusting turbidity, dip a sterile cotton swab into the inoculum and

rotate against the wall of the tube above the liquid to remove excess

inoculum.

- Swab entire surface of agar

plate three times, rotating plates approximately 60˚ between streaking to

ensure even distribution. Avoid hitting the slides of the plate to avoid

aerosols. Finally, run swab around the edge of the agar to remove any

excess moisture.

- Allow inoculated plate to

stand for 3 to 15 min before applying discs.

- Application of discs

- Apply disc to agar surface

with dispenser or manually with a sterile forceps.

- Apply gentle pressure with

sterile forceps or needle to ensure complete contact of disc with agar.

- Do not place discs closer

than 24mm from center to center (no more than 12 discs on 150 mm plates

and 5 discs on 100 mm plates.

- Do not relocate a disc once

it has made contact with agar surface. Instead, place a new disc in

another location on the agar.

- Incubation

- Invert plates and incubate

within 15 min of disc application.

- Incubate for 16 to 18 at 35˚C

in an ambient air incubator.

- Reading plates

- Read plates only if lawn of

growth is confluent or nearly confluent.

- Hold inverted plate a few

inches above a black nonreflecting surface.

- Illuminate plate with

reflected light.

- Use a sliding caliper or

ruler held on the back of the plate to measure the diameter of inhibition

zone to nearest whole millimeter.

- When measuring zones for

sulfonamides, trimethoprim, or trimethoprim- sulfamethoxazole, disregard

light growth (20% less of lawn of growth) and measure edge of the more

obvious margin of the zone.

- Discrete colonies growing

within the inhibition zone may represent a mixed culture or resistant

variants; subculture single colonies from the primary culture plate,

re-identify, and retest for susceptibility. If the discrete colonies are

still apparent, measure the colony – free inner zone.

G. Interpretation and Reporting

Use criteria specified by the CLSI to interpret the

zone of inhibition for each

antimicrobial agents and report categorical result as either

susceptible(S), intermediate (I), or resistant (R).

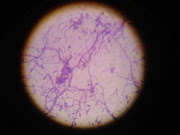

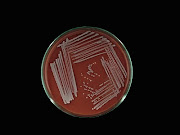

Figure

1: Antibiotic Susceptibility test of a bacterial isolate.

precautions

The

following common sources of error should be investigated to verify that:

- Zone

diameters were measured and transcribed correctly;

- The

turbidity standard has not expired, is stored properly, meets performance requirements,

and was adequately mixed prior to use;

- All

materials used were within their expiration dates and stored at the proper

temperature;

- The

incubator is at proper temperature and atmosphere;

- Other

equipment used (e.g., pipettors) are functioning properly;

- Discs are

stored desiccated and at proper temperature;

- The control

strain has not changed and is not contaminated;

- Inoculum

suspensions were prepared and adjusted correctly; and inoculum for the

test was prepared from a plate incubated for the correct length of time

and in no case more than 24 hours old.