CELL DISRUPTION

Introduction

Biological products synthesized by

fermentation or cell culture are either intracellular or extracellular.

Intracellular products either occur in a soluble form in the cytoplasm or are

produced as inclusion bodies (fine particles deposited within the cells).

Examples of intracellular products include recombinant insulin and recombinant

growth factors. A large number of recombinant products are found as inclusion

bodies in order to accumulate in larger quantities within the cells. In order

to obtain intracellular products the cells first have to be disrupted to

release these into a liquid medium before further separation can be carried

out. Certain biological products have to be extracted from tissues, an example

being porcine insulin which is obtained from pig pancreas. In order to obtain

such a tissue derived substance, the source tissue first needs to be

homogenized or ground into a cellular suspension and the cells are then

subjected to cell disruption to release the product into a solution. In the

manufacturing process for intracellular products, the cells are usually first

separated from the culture liquid medium. This is done in order to reduce the

amount of impurity: particularly secreted extracellular substances and

unutilized media components. In many cases the cell suspensions are thickened

or concentrated by microfiltration or centrifugation in order to reduce the

process volume.

Several

factors must be considered.

Volume or sample size of cells to be disrupted

If

only a few microliters of sample are available, care must be taken to minimize

loss and to avoid cross-contamination.

Disruption

of cells, when hundreds or even thousands of liters of material are being

processed in a production environment, presents a different challenge.

Throughput, efficiency, and reproducibility are key factors.

How many different samples need to be disrupted at one

time?

Frequently

when sample sizes are small, there are many samples. As sample sizes increase,

fewer samples are usually processed. Issues are sample cross contamination,

speed of processing, and equipment cleaning.

How easily are the cells disrupted?

As

the difficulty of disruption increases (e.g. E. coli),

more force is required to efficiently disrupt the cells. For even more

difficult samples (e.g. yeast), there is a parallel increase in the processor power

and cost. The most difficult samples (e.g. spores) require

mechanical forces combined with chemical or enzymatic efforts, often with

limited disruption efficiency.

What efficiency of disruption is required?

Over-disruption

may impact the desired product. For example, if subcellular fractionation studies are

undertaken, it is often more important to have intact subcellular components,

while sacrificing disruption efficiency.

For

production scale processes, the time to disrupt the cells and the

reproducibility of the method become more important factors.

How stable is the molecule(s) or component that needs

to be isolated?

In

general, the cell disruption method is closely matched with the material that

is desired from the cell studies. It is usually necessary to establish the

minimum force of the disruption method that will yield the best product.

Additionally, once the cells are disrupted, it is often essential to protect

the desired product from normal biological processes (e.g. proteases) and from

oxidation or other chemical events.

What purification methods will be used following cell

disruption?

It

is rare that a cell disruption process produces a directly usable material; in

almost all cases, subsequent purification events are necessary. Thus, when the

cells are disrupted, it is important to consider what components are present in

the disruption media so that efficient purification is not impeded.

Is the sample being subjected to the method

biohazardous?

Preparation

of cell-free extracts of pathogens presents unique difficulties. Mechanical

disruption techniques are not always applicable owing to potential biohazard

problems associated with contamination of equipment and generation of aerosols.

Cells

Different types of cell need to be disrupted in the bioindustry:

·

Gram positive

bacterial cells

·

Gram negative

bacterial cells

·

Yeast cell

·

Mould cells

·

Cultured

mammalian cells

·

Cultured plant

cells

·

Ground tissue

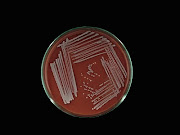

Bacterial cells:

The cell wall of Gram positive bacteria is thick and mainly composed of thick

layer of peptidoglycan layer. While the plasma or cell membrane which is made

up of phospholipids and proteins is relatively fragile. In certain cases

polysaccharide capsules may be present outside the cell wall. The cell wall of

gram positive bacteria is particularly susceptible to lysis by the antibacterial enzyme, lysozyme. Unlike gram positive bacteria,

gram negative bacteria do not have distinct cell walls but instead have multilayered

envelops. The peptidoglycan layer is

significantly thinner than in gram positive bacteria. An external layer composed of lipopolysaccharides and

proteins is usually present. Another difference with gram positive bacteria is

the presence of the periplasm layers which are two liquid filled gaps, one

between the plasma membrane and the peptidoglycan layer and the other between

the peptidoglycan layer and the external lipopolysaccharides. Periplasmic

layers also exits in gram positive bacteria but these are significantly thinner

than those in gram negative bacteria. The periplasm is important in

bioprocessing since a large number of proteins, particularly recombinant

proteins are secreted into it. An elegant way to recover the periplasmic

proteins is by the use of osmotic shock. This technique is discussed below.

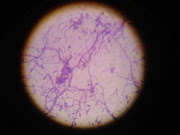

Yeast/Mould cells: Yeasts which are unicellular have thick cell

walls, typically 0.1 to 0.2 microns in thickness. These are mainly composed of

polysaccharides such as glucans, mannans and chitins. The plasma membrane in a

yeast cell is composed of phospholipids and lipoproteins. Mould cells are

largely similar to yeast cells in terms of cell wall and plasma membrane

composition but are multicellular and filamentous.

Mammalian cells: Mammalian cells do not possess the cell wall and

are hence quite fragile i.e. easy to disrupt.

Plant cells: Plant cells on the other hand have very thick cell

walls mainly composed of cellulose and other polysaccharides. Cell wall

wherever present is the main barrier which needs to be disrupted to recover

intracellular products. A range of mechanical methods can be used to disrupt

the cell wall. Chemical methods when used for cell disruption are based on

specific targeting of key cell wall components. For instance, lysozyme is used

to disrupt the cell wall of gram positive bacteria since it degrades

peptidoglycan which is a key cell wall constituent. In gram negative bacteria,

the peptidoglycan layer is less susceptible to lysis by lysozyme since it is

shielded by a layer composed of lipopolysaccharides and proteins.

Cell membranes: Cell membranes or plasma membranes are composed of

phospholipids arranged in the form of a bilayer with the hydrophilic groups of

the phospholipids molecules facing outside (Figure below). The hydrophobic residues

remain inside the cell membrane where they are shielded from the aqueous

environment present both within and outside the cell. The plasma membrane can

be easily destabilized by detergents, acid, alkali and organic solvents. The

plasma membrane is also quite fragile when compared to the cell wall and can

easily be disrupted using osmotic shock i.e. by suddenly changing the osmotic

pressure across the membrane. This can be achieved simply by transferring the

cell from isotonic medium to distilled water.

Figure 1:

Plasma membrane

Cell disruption

methods can be classified into two categories: Mechanical methods and Non-mechanical

methods.

A. Mechanical Methods of Cell Disruption: uses mechanical forces to disintegrate the

cells like soli shearing, liquid shearing, pressure etc. Some methods are:

1.

Disruption in bead mill

2.

Disruption using

a rotor stator mill

3.

Homogenization

4.

Disruption using

French press

5.

Disruption using

ultrasonic vibrations

B. Non-mechanical

Methods of Cell Disruption: includes physical, chemical and biological

treatment of cells to disrupt the cells.

1. Physical methods

a. Disruption using osmotic shock

b. Freeze-thaw method

2. Chemical methods

a.

Detergents

b. Solvents

c. Acid

and alkali methods

3. Biological methods

a.

Enzymes e.g.

lysozyme

b.

Phage

c.

Autolysis

The mechanical methods are targeted more towards cell

wall disruption while the non-mechanical methods are mainly used for

destabilizing the cell membrane.

A.

Mechanical methods for cell disruption

1. Cell disruption using bead mill

Bead mill equipment consists of a tubular

vessel made of metal or thick glass within which the cell suspension is placed

along with small metal or glass beads. The tubular vessel is then rotated about

its axis and as a result of this the beads start rolling away from the

direction of the vessel rotation. At higher rotation speeds, some the beads

move up along with the curved wall of the vessel and then cascade back on the

mass of beads and cells below. The cell disruption takes place due to the

grinding action of the rolling beads as well as the impact resulting from the

cascading beads.

Figure 2:

Cell disruption by Bead Milling

Bead milling can generate enormous

amounts of heat. While processing thermolabile material, the milling can be

carried out at low temperatures, i.e. by adding a little liquid nitrogen into

the vessel. This is referred to as cryogenic bead milling. An alternative

approach is to use glycol cooled equipment. A bead mill can be operated in a

batch mode or in a continuous mode and is commonly used for disrupting yeast

cells and for grinding animal tissue. Using a small scale unit operated in a

continuous mode, a few kilograms of yeast cells can be disrupted per hour.

Larger unit can handle hundreds of kilograms of cells per hour.

Disadvantages:

- Occasional

problems with foaming and sample heating, especially for larger samples.

- Tough

tissue samples such as skin or seeds are difficult to disrupt unless the

sample is very small or has been pre-chopped into small pieces.

2. Cell disruption using rotor-stator mill

A rotor-stator mill device consists of a

stationary block with a tapered cavity called the stator and a truncated cone

shaped rotating object called the rotor. Typical rotation speeds are in the

10,000 to 50,000 rpm range. The cell suspension is fed into the tiny gap

between the rotating rotor and the fixed stator. The feed is drawn in due to

the rotation and expelled through the outlet due to centrifugal action. The

high rate of shear generated in the space between the rotor and the stator as

well as the turbulence thus generated are responsible for cell disruption.

These mills are more commonly used for disruption of plant and animal tissues

based material and are operated in the multipass mode, i.e. the disrupted

material is sent back into the device for more complete disruption. The cell

disruption caused within the rotor-stator mill can be described using the

equations discussed for a bead mill.

Figure 3:

Cell disruption using rotor-stator mill

3. Homogenization

Liquid

based homogenization is the most widely used cell disruption technique for

small volumes and cultured cells. Cells are lysed by forcing the cell or tissue

suspension through a narrow space known as clearance space (0.001 mm- 0.006 mm),

thereby shearing the cell membranes. Three different types of homogenizers are

in common use. A Dounce homogenizer consists of a round glass pestle that is

manually driven into a glass tube. A Potter-Elvehjem homogenizer consists of a

manually or mechanically driven Teflon pestle shaped to fit a rounded or

conical vessel. The number of strokes and the speed at which the strokes are

administered influences the effectiveness of Dounce and Potter-Elvehjem

homogenization methods. Both homogenizers can be obtained in a variety of sizes

to accommodate a range of volumes.

Figure 4: Cell

disruption using homogenizer

4. Cell disruption using French press

A French

press is a device commonly used for small scale recovery of intracellular

proteins and DNA from bacterial and plant cells. The device consists of a

cylinder fitted with a plunger which is connected to a hydraulic press. The

cell suspension is placed within the cylinder and pressurized using the

plunger. The cylinder is provided with an orifice through which the suspension

emerges at very high velocity in the form of a fine jet. The cell disruption

takes place primarily due to the high shear rates and differential pressure. The internal FRENCH Pressure Cell pressure

increases as the pressure developed by the Laboratory Press increases. The

intracellular pressure increases as well. As the sample is dispensed through

the sample outlet tube, the external pressure on the cell wall drops rapidly

toward atmospheric pressure. The pressure within the cell drops as well but not

as quickly as the pressure external to the cell. This pressure differential

causes the cell wall membrane to burst, releasing the intra-cellular contents. A French press is frequently provided with an impact

plate, where the jet impinges causing further cell disruption. Typical volumes

handled by such devices range from a few milliliters to a few hundred milliliters.

Typical operating pressure ranges from 10,000 to 50,000 psi.

Advantages:

— This technique results in more uniform and

complete disruption

— Cells do not require pre-treating.

— Easy to use

Figure 5:

Cell disruption using French press

5. Cell disruption using ultrasonic vibrations

Ultrasonic vibrations (i.e. having

frequency greater than 18 kHz) can be used to disrupt cells. The cells are

subjected to ultrasonic vibrations by introducing an ultrasonic vibration

emitting tip into the cell suspension (Figure below). Ultrasound emitting tips

of various sizes are available and these are selected based on the volume of

sample being processed. The ultrasonic vibration could be emitted continuously

or in the form of short pulses. A frequency of 25 kHz is commonly used for cell

disruption. The duration of ultrasound needed depends on the cell type, the

sample size and the cell concentration. These high frequency vibrations cause

cavitations, i.e. the formation of tiny bubbles within the liquid medium. When

these bubbles reach resonance size, they collapse releasing mechanical energy

in the form of shock waves equivalent to several thousand atmospheres of

pressure. The shock waves disrupt cells present in suspension. For bacterial

cells such as E. coli, 30 to 60

seconds may be sufficient for small samples. For yeast cells, this duration

could be anything from 2 to 10 minutes.

Ultrasonic vibration is frequently used

in conjunction with chemical cell disruption methods. In such cases the

barriers around the cells are first weakened by exposing them to small amounts

of enzymes or detergents. Using this approach, the amount of energy needed for

cell disruption is significantly reduced.

Disadvantages:

- Heat

generated by the ultrasound process must be dissipated.

- High noise

levels (most systems require hearing protection and sonic enclosures)

- Yield

variability

- Free radicals are generated that can react with other molecules.

Figure 6: Cell disruption by sonication

6. Mortar and Pestle

It is

a manual grinding method, most commonly used to disrupt plant cells. In this

method, tissue is frozen in liquid nitrogen and then crushed using a mortar and

pestle. Because of tensile strength of the cellulose and other polysaccharides

comprising the cell wall, this method is the fastest and most efficient way to

access plant protein and DNA.