Factors

affecting microbial spoilage of pharmaceutical products

By

understanding the influence of environmental parameters on microorganisms, it

may be possible to manipulate formulations to create conditions which are as

unfavorable as possible for growth and spoilage, within the limitations of

patient acceptability and therapeutic efficacy.

Types

and size of contaminant inoculum

When

failures inevitably occur from time to time, knowledge of the microbial ecology

and careful identification of contaminants can be most useful in tracking down

the defective steps in the design or production process. Low levels of

contaminants may not cause appreciable spoilage, if unable to replicate in a

product; however, an unexpected surge in the contaminant bioburden may present

an unacceptable challenge to the designed formulation. This could arise as if

there was a lapse in the plant-cleaning protocol; a biofilm detached itself

from within supplying pipework; or the product had been grossly misused during

administration. Inoculum size alone is not always a reliable indicator of

likely spoilage potential. Low levels of aggressive pseudomonads in a weakly

preserved solution may suggest a greater risk than tablets containing fairly

high numbers of

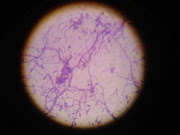

fungal

and bacterial spores.

When

an aggressive microorganism contaminates a medicine, there may be an

appreciable lag period before significant spoilage begins, the duration of

which decreases disproportionately with increasing contaminant loading. As

there is usually a considerable delay between manufacture and administration of

factory-made medicines, growth and attack could ensue during this period unless

additional steps were taken to prevent it.

The

isolation of a particular microorganism from a markedly spoiled product does

not necessarily

mean

that it was the initiator of the attack. It could be a secondary opportunist

contaminant which had overgrown the primary spoilage organism once the physicochemical

properties had been favourably modified by the primary spoiler.

Nutritional

factors

Microorganisms

enable them to utilize many formulation components as substrates for

biosynthesis and growth. The use of crude vegetable or animal products in a

formulation provides an additionally nutritious environment. Even demineralized

water prepared by good ion-exchange methods will normally contain sufficient

nutrients to allow significant growth of many waterborne Gram-negative bacteria

such as Pseudomonas spp. When such contaminants fail to survive, it is

unlikely to be the result of nutrient limitation in the product but due to other,

non-supportive, physicochemical or toxic properties.

Acute

pathogens require specific growth factors normally associated with the tissues

they infect but which are often absent in pharmaceutical formulations. They are

thus unlikely to multiply in them, although they may remain viable and

infective for an appreciable time in some dry products where the conditions are

suitably protective.

Moisture

content: water activity (Aw)

Microorganisms

require readily accessible water in appreciable quantities for growth to occur.

By measuring a product’s water activity (Aw), it is possible to

obtain an estimate of the proportion of uncomplexed water that is available in

the formulation to support microbial growth, using the formula: Aw

= vapour pressure of formulation/vapour pressure of water under similar

conditions.

The

greater the solute concentration, the lower is the water activity. With the

exception of halophilic bacteria, most microorganisms grow best in dilute solutions

(high Aw) and, as solute concentration rises (lowering Aw),

growth rates decline until a minimal growth-inhibitory Aw, is reached.

The

Aw of aqueous formulations can be lowered to increase resistance to

microbial attack by the addition of high concentrations of sugars or polyethylene

glycols. Aw can also be reduced by drying, although the dry, often

hygroscopic medicines (tablets, capsules, powders) will require suitable

packaging to prevent resorption of water and consequent microbial growth.

Condensation

similarly formed on the surface of viscous products such as syrups and creams,

or exuded by syneresis from hydrogels, may well permit surface yeast and fungal

spoilage.

Redox

potential

The

ability of microbes to grow in an environment is influenced by its

oxidation-reduction balance (redox potential), as they will require compatible terminal

electron acceptors to permit their respiratory pathways to function. The redox

potential even in fairly viscous emulsions may be quite high due to the

appreciable solubility of oxygen in most fats and oils.

Storage

temperature

Spoilage

of pharmaceuticals could occur potentially over the range of about -20°C to

60°C, although it is much less likely at the extremes. The particular storage

temperature may selectively determine the types of microorganisms involved in

spoilage. A deep freeze at -20°C or lower is used for long-term storage of some

pharmaceutical raw materials and short-term storage of dispensed total

parenteral nutrition (TPN) feeds prepared in hospitals. Reconstituted syrups

and multi-dose eye-drop packs are sometimes dispensed with the instruction to

‘store in a cool place’ such as a domestic fridge (8°–12°C), partly to reduce

the risk of growth of contaminants inadvertently introduced during use.

Conversely, Water for Injections (EP) should be held at 80°C

or

above after distillation and before packing and sterilization to prevent

possible regrowth of Gram negative bacteria and the release of endotoxins.

pH

Extremes

of pH prevent microbial attack. Around neutrality,

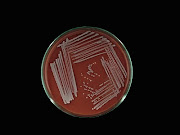

bacterial spoilage is more likely, with reports of pseudomonads and related Gram-negative

bacteria growing in antacid mixtures, flavoured mouthwashes and in distilled or

demineralized water. Above pH 8 (e.g. with soap-based emulsions) spoilage is

rare. In products with low pH levels (e.g. fruit juice-flavoured syrups with a

pH 3–4), mould or yeast attack is more likely. Yeasts can metabolize organic

acids and raise the pH to levels where secondary bacterial growth can occur.

Although the use of low pH adjustment to preserve foodstuffs is well

established (e.g. pickling, coleslaw, yoghurt), it is not practicable to make

deliberate use of this for medicines.

Packaging

design

Packaging

can have a major influence on microbial stability of some formulations in

controlling the entry of contaminants during both storage and use. Considerable

thought has gone into the design of containers to prevent the ingress of

contaminants into medicines for parenteral administration, owing to the high

risks of infection by this route. Self-sealing rubber wads must be used to

prevent microbial entry into multi-dose injection containers following

withdrawals with a hypodermic needle.

Where

medicines rely on their low Aw to prevent spoilage, packaging

such as strip foils must be of water vapour-proof materials with fully efficient

seals. Cardboard outer packaging and labels themselves can become substrates

for microbial attack under humid conditions, and preservatives are often

included to reduce the risk of damage.

Protection

of microorganisms within pharmaceutical products

The

survival of microorganisms in particular environments is sometimes influenced

by the presence of relatively inert materials. Thus, microbes can be more

resistant to heat or desiccation in the presence of polymers such as starch,

acacia or gelatin. Adsorption onto naturally occurring particulate material may

aid establishment and survival in some environments. There is a belief, but

limited hard evidence, that the presence of suspended particles such as kaolin,

magnesium trisilicate or aluminium hydroxide gel may influence contaminant

longevity in those products containing them, and that the presence of some

surfactants, suspending agents and proteins can increase the resistance of

microorganisms to preservatives, over and above their direct inactivating effect

on the preservative itself.