Bidur Dhungel1, Manoj Subedi1, Kiran Babu Tiwari1,2, Upendra Thapa Shrestha2, Subarna Pokhrel3 and Vishwanath Prasad Agrawal1, 2

(1) Universal science College, Pokhara University, Kathmandu, Nepal

(2) Research Laboratory for Agricultural Biotechnology and Biochemistry, Kathmandu, Nepal

(3) Department of Enzyme Engineering, Seoul National University, Korea

Corresponding Address: Dr. Vishwanath P. Agrawal, Professor of Biochemistry, Universal Science College, Pokhara University, Kathmandu. Email: vpa@wlink.com.np

ABSTRACT

(1) Universal science College, Pokhara University, Kathmandu, Nepal

(2) Research Laboratory for Agricultural Biotechnology and Biochemistry, Kathmandu, Nepal

(3) Department of Enzyme Engineering, Seoul National University, Korea

Corresponding Address: Dr. Vishwanath P. Agrawal, Professor of Biochemistry, Universal Science College, Pokhara University, Kathmandu. Email: vpa@wlink.com.np

ABSTRACT

Glucose isomerase (EC 5.3.1.5) was extracted from Streptomyces spp., isolated from Mt. Everest soil sample, and purified by ammonium sulfate fractionation and Sepharose-4B chromatography. A 7.1 fold increase in specific activity of the purified enzyme over crude was observed. Using glucose as substrate, the Michaelis constant (KM) and maximal velocity (Vmax) were found to be 0.45M and 0.18U/mg. respectively. The optimum substrate (glucose) concentration, optimum enzyme concentration, optimum pH, optimum temperature, and optimum reaction time were 0.6M, 62.14μg/100μl, 6.9, 70ºC, and 30 minutes, respectively. Optimum concentrations of Mg2+ and Co2+ were 5mM and 0.5mM, respectively. The enzyme was thermostable with half-life 30 minutes at 100ºC.

INTRODUCTION

Glucose isomerase (EC 5.3.1.9), GI, is an intracellular bacterial enzyme1 that catalyzes the reversible isomerization of glucose to fructose or xylose to xylulose2. Fructose is the sweetest of various naturally occurring sugars and there has long been a demand for it as alternative to sucrose. GI is one of the three highest tonnage value enzymes, amylases and proteases being the other two.3 The enzyme is used to produce high-fructose corn syrup from corn starch. This process involves several separate enzymatic steps, including liquefaction of corn starch by a-amylase, saccharification by glucoamylase, and isomerization by glucose isomerase.4

Most commercially available GI has been isolated from mesophilic microorganisms, including Streptomyces, Actinoplanes, Flavobacterium and Bacillus spp.3 GIs are homotetramer with 45kDa or 49kDa, the former being more conservative.5- 9 Most of the GIs are not highly thermostable (limited to 60ºC only) and less active at neutral. Thermostable GIs with neutral or slightly acidic pH optima have a potential for industrial applications. The thermo-acid-stable GI allow for faster reaction rates, higher fructose concentration at equilibrium, higher process stability, decreased viscosity of substrate and product streams, and reduced by-product formation.10

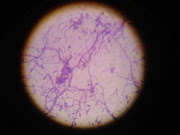

Owing to the industrial significance of the enzyme, GI from various microorganisms has been studied and their catalytic and physicochemical properties have been reviewed.11,12 Thermophilic microorganisms produce industrially thermostable enzymes which have been evolved and adapted to the extreme environment of their natural habitats. As the Research Laboratory for Agricultural Biotechnology and Biochemistry (RLABB) has been studying and exploiting the actinomycetes’ population diversity from high altitude ecological niche, this work was done on D-glucose isomerase of the psychrotolerant Streptomyces spp. isolated from the soil sample collected from Khumbu, Mount Everest base camp.

METHODOLOGY

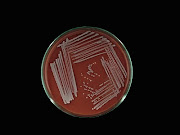

Culture: Streptomyces spp. Lob 15.4, isolated from soil samples collected from Lobuche, Mt. Everest base camp, was revived by inoculating spores into a 250 ml conical flask containing 50 ml of culture medium (1% tryptone, 0.7% yeast extract, 1% xylose and 0.1%MgSO4.7H2O, pH 7.0-7.2) followed by incubating at 28ºC in a shaker waterbath (200rpm) for 4 days.13

Enzyme preparation: Streptomyces cells were collected by centrifugation, washed several times with deionised water and homogenized in vertexer in 0.1M phosphate buffer (pH 7.0) containing 5mM MgSO4, 0.5mM CoCl2 and 1mM PMSF. Cells were disrupted in a bath sonicator for 30 min with ice and centrifug at 10000 rpm for 20 min at 4ºC to obtain enzyme supernant.13

Enzyme assay: A 100ml of the enzyme was incubated in 900ml phosphate buffer (pH 7.0) containing 5mM MgSO4, 0.5mM CoCl2 and 0.8M glucose at 37ºC for 40 minutes, followed by keeping the tubes in an ice bath. The amount of the product, fructose, was determined by Seliwanoff’s method.10

Protein determination: Protein content in the supernatant was determined by Bradford assay.14

Enzyme purification: Ammonium sulphate was added to the crude enzyme extract to 45% saturation, incubated for an hour at 4ºC with gentle mixing. The precipitate was collected by centrifugation at 10,000 rpm for 20 min at 4ºC and dissolved in 0.1M phosphate buffer (pH 7.0) containing 5mM MgSO4, 0.5mM CoCl2. The ammonium sulphate concentration was increased stepwise to 60%, 75% and finally to 90% saturation; and the precipitates were harvested accordingly. The fraction containing glucose isomerase activity was pooled and dialyzed overnight against 0.1M-phosphate buffer (pH 7.0).15 Then, a Sepharose 4B column (3.2 by 38.5cm) was prepared and equilibrated with 0.05M phosphates buffer containing 0.15M NaCl. The dialyzed enzyme was applied to the column and eluted with the phosphate buffer. Fraction containing glucose isomerase activity was collected, concentrated with ammonium sulphate and dialyzed against 0.1M phosphate buffer (pH 7.0).15 The purification steps were monitored by SDS-PAGE16 and Native-PAGE17.

Optimization: Optimization was done in phosphate buffer (pH 7.0) containing 5mM MgSO4, 0.5mM CoCl2 at 37ºC for 40 min. unless mentioned otherwise. Glucose (substrate) from 0.1-1.0M and enzyme from 6-124µg were mixed in the respective optimization reaction. Phosphate buffers from pH 4-10 were used to optimize pH of the respective reaction with 0.6M glucose. Time and temperature were optimized by incubation the respective reaction mixtures for 10 to 60 minutes and 30 to 90ºC in phosphate buffer with pH 6.9. To optimize Mg2+ and Co2+ concentrations, 0.05-10mM ions were mixed in the respective reaction buffer. Amount of product (fructose) produced was determined by Seliwanoff’s method.10

Half-life and Thermal stability were determined by measuring residual activity under optimum assay condition after pre-incubation of the enzyme- at 100ºC for 5-30 minutes for half life and at 40-90ºC for 30 to 150 minutes for thermal stability.15

RESULT

Most commercially available GI has been isolated from mesophilic microorganisms, including Streptomyces, Actinoplanes, Flavobacterium and Bacillus spp.3 GIs are homotetramer with 45kDa or 49kDa, the former being more conservative.5- 9 Most of the GIs are not highly thermostable (limited to 60ºC only) and less active at neutral. Thermostable GIs with neutral or slightly acidic pH optima have a potential for industrial applications. The thermo-acid-stable GI allow for faster reaction rates, higher fructose concentration at equilibrium, higher process stability, decreased viscosity of substrate and product streams, and reduced by-product formation.10

Owing to the industrial significance of the enzyme, GI from various microorganisms has been studied and their catalytic and physicochemical properties have been reviewed.11,12 Thermophilic microorganisms produce industrially thermostable enzymes which have been evolved and adapted to the extreme environment of their natural habitats. As the Research Laboratory for Agricultural Biotechnology and Biochemistry (RLABB) has been studying and exploiting the actinomycetes’ population diversity from high altitude ecological niche, this work was done on D-glucose isomerase of the psychrotolerant Streptomyces spp. isolated from the soil sample collected from Khumbu, Mount Everest base camp.

METHODOLOGY

Culture: Streptomyces spp. Lob 15.4, isolated from soil samples collected from Lobuche, Mt. Everest base camp, was revived by inoculating spores into a 250 ml conical flask containing 50 ml of culture medium (1% tryptone, 0.7% yeast extract, 1% xylose and 0.1%MgSO4.7H2O, pH 7.0-7.2) followed by incubating at 28ºC in a shaker waterbath (200rpm) for 4 days.13

Enzyme preparation: Streptomyces cells were collected by centrifugation, washed several times with deionised water and homogenized in vertexer in 0.1M phosphate buffer (pH 7.0) containing 5mM MgSO4, 0.5mM CoCl2 and 1mM PMSF. Cells were disrupted in a bath sonicator for 30 min with ice and centrifug at 10000 rpm for 20 min at 4ºC to obtain enzyme supernant.13

Enzyme assay: A 100ml of the enzyme was incubated in 900ml phosphate buffer (pH 7.0) containing 5mM MgSO4, 0.5mM CoCl2 and 0.8M glucose at 37ºC for 40 minutes, followed by keeping the tubes in an ice bath. The amount of the product, fructose, was determined by Seliwanoff’s method.10

Protein determination: Protein content in the supernatant was determined by Bradford assay.14

Enzyme purification: Ammonium sulphate was added to the crude enzyme extract to 45% saturation, incubated for an hour at 4ºC with gentle mixing. The precipitate was collected by centrifugation at 10,000 rpm for 20 min at 4ºC and dissolved in 0.1M phosphate buffer (pH 7.0) containing 5mM MgSO4, 0.5mM CoCl2. The ammonium sulphate concentration was increased stepwise to 60%, 75% and finally to 90% saturation; and the precipitates were harvested accordingly. The fraction containing glucose isomerase activity was pooled and dialyzed overnight against 0.1M-phosphate buffer (pH 7.0).15 Then, a Sepharose 4B column (3.2 by 38.5cm) was prepared and equilibrated with 0.05M phosphates buffer containing 0.15M NaCl. The dialyzed enzyme was applied to the column and eluted with the phosphate buffer. Fraction containing glucose isomerase activity was collected, concentrated with ammonium sulphate and dialyzed against 0.1M phosphate buffer (pH 7.0).15 The purification steps were monitored by SDS-PAGE16 and Native-PAGE17.

Optimization: Optimization was done in phosphate buffer (pH 7.0) containing 5mM MgSO4, 0.5mM CoCl2 at 37ºC for 40 min. unless mentioned otherwise. Glucose (substrate) from 0.1-1.0M and enzyme from 6-124µg were mixed in the respective optimization reaction. Phosphate buffers from pH 4-10 were used to optimize pH of the respective reaction with 0.6M glucose. Time and temperature were optimized by incubation the respective reaction mixtures for 10 to 60 minutes and 30 to 90ºC in phosphate buffer with pH 6.9. To optimize Mg2+ and Co2+ concentrations, 0.05-10mM ions were mixed in the respective reaction buffer. Amount of product (fructose) produced was determined by Seliwanoff’s method.10

Half-life and Thermal stability were determined by measuring residual activity under optimum assay condition after pre-incubation of the enzyme- at 100ºC for 5-30 minutes for half life and at 40-90ºC for 30 to 150 minutes for thermal stability.15

RESULT

A maximum enzyme activity of broth was obtained after 96h (4days) of cultivation in media. Fraction collected during 90% saturation of ammonium sulphate showed glucose isomerase activity and was further purified by column chromatography to 7.1 fold increase in activity (Fig. 1). The purified fraction had specific activity 0.490U/mg (Fig. 2). Native-PAGE revealed that the enzyme had mol. wt. about 200kD. The Michaelis constant (KM) and maximal velocity (Vmax) were found to be 0.45M and 0.18U/mg (Fig. 3), respectively. The optimum substrate (glucose) concentration, optimum enzyme concentration, optimum pH, optimum temperature, and optimum reaction time were 0.6M (Fig. 43), 62.14μg/100μl (Fig. 5), 6.9 (Fig. 6), 70ºC (Fig. 7), and 30 minutes (Fig. 8), respectively. Optimum concentrations of Mg2+ and Co2+ were 5mM (Fig. 9) and 0.5mM (Fig. 10), respectively. The enzyme had half life 30 minutes at 100ºC (Fig. 11). The enzyme was quite thermostable (Fig. 12).

DISCUSSION:

The production of glucose isomerase from Streptomyces species has been documented by several investigators.18,19 The sample sonicated for 20minutes showed maximum enzyme activity.(13)

Chou and Anderson also found glucose isomerase activity in 90% ammonium sulfate saturation.20 To get more purified form of the enzyme, the chromatography has to be done several times. Chen and Anderson reported that the enzyme was purified using DEAE –Sephadex A-50 and the purification was about 12.6 fold over the crude.20 The enzyme activity was stable at 37ºC; therefore, all steps of purification were performed at that temperature. The purified fraction had specific activity 0.490U/mg and crude enzyme had 0.069 U/mg, suggesting a 7.1 fold increase in specific activity of the purified enzyme over crude was observed.

Homogeneity of the purified enzyme was determined by Sodium dodecyl sulphate -polyacrylamide gel electrophoresis (SDS-PAGE). The purified enzyme was homogeneous by the detection of a single protein band on SDS-PAGE and Native-PAGE. Approximately, mol. wt. of 200kD protein band on Native-PAGE and about 50kD on SDS-PAGE was determined, suggesting that the enzyme to be tetramer.

The enzyme also called as Xylose isomerase (XI) as it converts xylose to xylulose besides converting glucose to fructose. Hence, xylose was used as the inducer of the enzyme in the culture medium. The enzyme was, then, optimized using glucose as a substrate. The optimum glucose concentration was 0.6M. The Michaelis constant (KM) and maximal velocity (Vmax) were found to be 0.45M and 0.18U/mg. respectively. In the other studies the KM value upto 0.2M10 to 0.167M21 was also been reported. Lama et al. reported Vmax of 6.3U/mg.21 The enzyme with lower KM and higher Vmax towards substrate is more preferred for exploitation of enzyme behavior, suggesting the enzyme extract in the work may not be as competent to that obtained from mesophilic or thermophilic bacteria which are more suitably adapted to higher temperature.

The optimum pH is the ranges between pH 7.0 to 9.0.4 The optimum pH of the glucose isomerase is slightly acidic, pH 6.9. It was apparently lower than that of enzymes from other Streptomyes species.22 Therefore, a low pH optimum is an attractive property for enzyme application because the use of the enzyme at neutral or low pH prevents the formation of by-product, psicose.

Most of glucose isomerase isolated to date showed an optimum temperature around 80ºC.13 Most of the industrially exploitation of the enzyme is done at 60ºC, as Hodge indicated that degradation of ketoses occurs at high temperatures, characterized by pronounced discoloration of an aqueous sugar solution. Interestingly, in this study, the optimum temperature of the enzyme from the cold tolerant bacteria was 70ºC. This may be due to conservation of the gene in bacterial population.6-9 Lama et al. also documented that the kinetic characteristics for XI or GI were similar to XI from distantly related bacteria.21 The optimum temperature of the GI explored that psychrotolerant organisms may have thermostable proteins.

The optimum reaction time of the enzyme was 30min, similar to most of the enzymes from diversed bacteria.1,4,20 Compared to the half life reported by Chou et al13, 120h at 70ºC, the half life of the GI in this work was 30 minute at 100ºC, suggesting to be a quite thermostable one.

Glucose isomerases typically require the presence of divalent metal cations such Mg2+ or Co2+ as essential cofactors for their catalytic activity.23 Treatment of purified enzyme with EDTA resulted in an almost complete loss of enzyme activity. However, the activity could be restored by the addition of metal ions. In particular, increasing amounts of Mg2+ or Co2+ (each up to 10mM) were able to restore only 60-80% of the original xylose isomerase activity. Lama et al. reported, for glucose isomerase, 10mM Mg2+ was required to restore 80% of the original activity.21 As is common with other isomerases, 10mM Mg2+ plus 1mM Co2+ restored total glucose isomerase activity. However, the lower values of the cations observed in this study, suggested that the enzyme might be adapted in the ecological niche.

ACKNOWLEGMENT:

The production of glucose isomerase from Streptomyces species has been documented by several investigators.18,19 The sample sonicated for 20minutes showed maximum enzyme activity.(13)

Chou and Anderson also found glucose isomerase activity in 90% ammonium sulfate saturation.20 To get more purified form of the enzyme, the chromatography has to be done several times. Chen and Anderson reported that the enzyme was purified using DEAE –Sephadex A-50 and the purification was about 12.6 fold over the crude.20 The enzyme activity was stable at 37ºC; therefore, all steps of purification were performed at that temperature. The purified fraction had specific activity 0.490U/mg and crude enzyme had 0.069 U/mg, suggesting a 7.1 fold increase in specific activity of the purified enzyme over crude was observed.

Homogeneity of the purified enzyme was determined by Sodium dodecyl sulphate -polyacrylamide gel electrophoresis (SDS-PAGE). The purified enzyme was homogeneous by the detection of a single protein band on SDS-PAGE and Native-PAGE. Approximately, mol. wt. of 200kD protein band on Native-PAGE and about 50kD on SDS-PAGE was determined, suggesting that the enzyme to be tetramer.

The enzyme also called as Xylose isomerase (XI) as it converts xylose to xylulose besides converting glucose to fructose. Hence, xylose was used as the inducer of the enzyme in the culture medium. The enzyme was, then, optimized using glucose as a substrate. The optimum glucose concentration was 0.6M. The Michaelis constant (KM) and maximal velocity (Vmax) were found to be 0.45M and 0.18U/mg. respectively. In the other studies the KM value upto 0.2M10 to 0.167M21 was also been reported. Lama et al. reported Vmax of 6.3U/mg.21 The enzyme with lower KM and higher Vmax towards substrate is more preferred for exploitation of enzyme behavior, suggesting the enzyme extract in the work may not be as competent to that obtained from mesophilic or thermophilic bacteria which are more suitably adapted to higher temperature.

The optimum pH is the ranges between pH 7.0 to 9.0.4 The optimum pH of the glucose isomerase is slightly acidic, pH 6.9. It was apparently lower than that of enzymes from other Streptomyes species.22 Therefore, a low pH optimum is an attractive property for enzyme application because the use of the enzyme at neutral or low pH prevents the formation of by-product, psicose.

Most of glucose isomerase isolated to date showed an optimum temperature around 80ºC.13 Most of the industrially exploitation of the enzyme is done at 60ºC, as Hodge indicated that degradation of ketoses occurs at high temperatures, characterized by pronounced discoloration of an aqueous sugar solution. Interestingly, in this study, the optimum temperature of the enzyme from the cold tolerant bacteria was 70ºC. This may be due to conservation of the gene in bacterial population.6-9 Lama et al. also documented that the kinetic characteristics for XI or GI were similar to XI from distantly related bacteria.21 The optimum temperature of the GI explored that psychrotolerant organisms may have thermostable proteins.

The optimum reaction time of the enzyme was 30min, similar to most of the enzymes from diversed bacteria.1,4,20 Compared to the half life reported by Chou et al13, 120h at 70ºC, the half life of the GI in this work was 30 minute at 100ºC, suggesting to be a quite thermostable one.

Glucose isomerases typically require the presence of divalent metal cations such Mg2+ or Co2+ as essential cofactors for their catalytic activity.23 Treatment of purified enzyme with EDTA resulted in an almost complete loss of enzyme activity. However, the activity could be restored by the addition of metal ions. In particular, increasing amounts of Mg2+ or Co2+ (each up to 10mM) were able to restore only 60-80% of the original xylose isomerase activity. Lama et al. reported, for glucose isomerase, 10mM Mg2+ was required to restore 80% of the original activity.21 As is common with other isomerases, 10mM Mg2+ plus 1mM Co2+ restored total glucose isomerase activity. However, the lower values of the cations observed in this study, suggested that the enzyme might be adapted in the ecological niche.

ACKNOWLEGMENT:

We express our especial thank to Mr. Yogan Khatri, Mr. Deepak Singh and Rajendra Aryal for collecting soil samples from Mount Everest region and all the staffs of RLABB.

REFERENCES:

1. Chen WP (1980). Glucose Isomerase. Proc Biochem 15: 30-41.

2. Tsumura N and T Sato (1961). Enzymatic conversion of D-glucose to D-Fructose: Identification of active bacterial strain and conformation of D-Fructose formation. Agric Biol Chem 25:616-619.

3. Bhosale SH., MB Rao and VV Deshpande (1996). Molecular and industrial aspects of glucose isomerase. Microbiol Rev 60:280-300.

4. Lee C and JG Zeikus (1991). Purification and characterization of thermostable glucose isomerase from Clostridium thermosulfurogenes and Thermoanaerobacter stain B6A. Biochem J 274: 565-571.

5. Kwon, HJ., Kitada, M., Horikoshi K. (1987).Purification and properties of D-xylose isomerase from alkaliphilic Bacillus no KX-6. Agric Biol Chem 51:1983-1989.

6. CarrelHL., BH Rubin, TJ Hurley and JP Glusker (1984). X-ray crystal structure of D-xylose isomerase at 4-A resolution. J Biol Chem 259:3230-3236.

7. Farber GK, A Glasfeld, G Tiraby, G Ringe and GA Petsko (1989). Crystallographic studies on the mechanism of xylose isomerase. Biochemistry 28: 7289-7297.

8. Dauter Z, M Dauter, J Hemker, H Witzel and KS Wilson (1989) Crystallization and preliminary analysis of glucose isomerase from Streptomyces albus. FEBS Lett 247:1-8.

9. Henrick K, CA Collyer and DM Blow (1989) Structures of D-xylose isomerase from Arthrobacter Strain B3728 containing the inhibitors xylitol and D-sorbitol at 2.5A and 2.3A resolution, respectively. J Mol Biol 208: 129-157.

10. Chen, WP., AW. Anderon, and YW. Han.(1979) Production of glucose isomerase by Streptomyces flavogriseus. Appl. Environ. Microbiol. 37:785-787.

11. Chen WP (1980) Glucose isomerase (a review). Process Biochem June/July: 30-35.

12. Chen WP (1980) Glucose isomerase (a review). Process Biochem August/September: 36-41.

13. Chou CC, MR Ladisch and GT Tsao (1976) Studies on glucose isomerase from Streptomyces spp. Appl Environ Microbiol 32: 489-493.

14. Bradford MM (1976) A rapid and sensitive method for quantization of microgram quantities of protein using the principles of protein-dye binding. Anal Biochem 72: 248-254.

15. Liu SY, J Wiegel and FC Gherardini (1996) Purification and cloning of a thermostable xylose (glucose) isomerase with an acidic pH optimum from Thermoanaerobacterium strain JW/ SL-YS 489. J Bacteriol 178: 5938-5945.

16. Laemmli, UK (1970) Cleavage of structural proteins during assembly of The head of bacteriophage T4. Nature 277: 680-685.

17. Blackshear PJ (1984) Systems for polyacrylamide gel electrophoresis. In Methods in enzymology (Jakoby WB eds.) vol 104: 237-255.

18. Takasaki Y (1966) Studies on sugar isomerizing enzyme. Production and utilization of glucose isomerase from Streptomyces spp. Agric Biol Chem 30: 1247-1253.

19. Strandberg GW and KL Smiley (1971). Free and immobilized glucose Isomerase from Streptomyces phaeochromogenes. Appl Microbiol 21: 588-593.

20. Antrim RL, W Colilla and BJ Schnyder (1979). Glucose isomerase production of high fructose syrups. Appl Microbiol Biotechnol 2: 97-155.

21. Lama L, V Nicolaus, V Calandrelli, I Romano, R Basile and A Gambacorta (2001). Purification and characterization of thermostable xylose (glucose) isomerase from Bacillus thermoantarcticus. J Microbiol Biotechnol 27: 234-240.

22. Bucke C (1997). Industrial glucose isomerase In A Wiseman (ed.). Topics in enzyme and fermentation biotechnology. Ellis Horwood Limited. pp. 147-171.

23. Whitlow M, AJ Howard, BC Finzel, TL Poulos, E Winborne and GL Gilliland (1991). A metal-mediated hydride shift mechanism for xylose isomerase based on the 1.6A Streotomyces rubiginous structures with xylitol and D-xylose. Proteins 9: 153-173.

2 comments:

You gave fantastic honest ideas here. I performed a research on the issue and discovered that almost everyone is agreeing with your blog. Thanks so much for this! I have not been to such as great post for a long time! You’ve got it, whatever that means in blogging. Well, you’re definitely somebody who has something to say that people need to hear. Keep up the great job. Keep on inspiring the people!

Recombinant proteins

Isomers present in many varieties can generally be divided into structural isomers and stereoisomers. Structural isomers have a different sequence and/or different connectivity of bonds from one another. Stereoisomers with the same ordering of individual bonds and the same connection type differ in the three-dimensional arrangement of bonded atoms. isomerase introduction

Post a Comment